Impact Echo

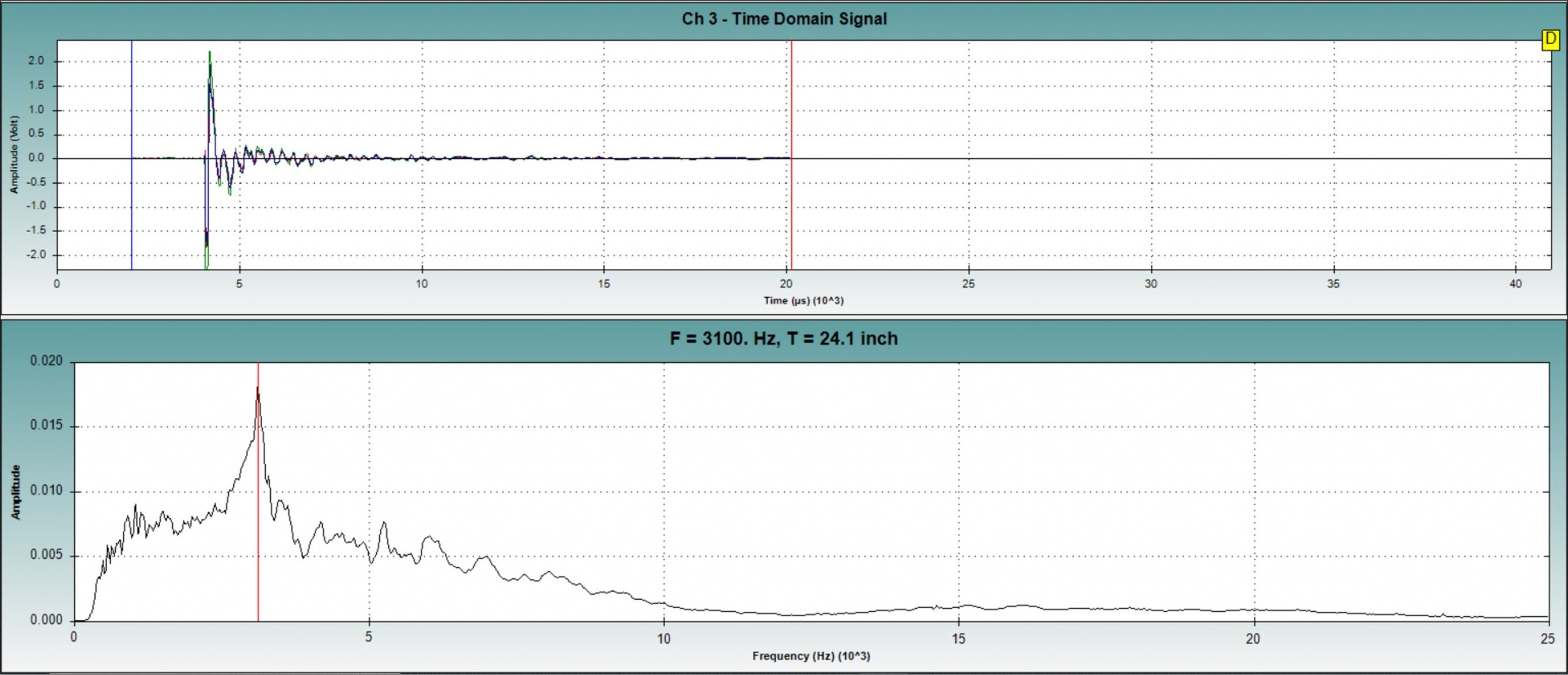

The Impact Echo (IE) method is used for rapid flaw detection and thickness evaluation of concrete and masonry structural materials.

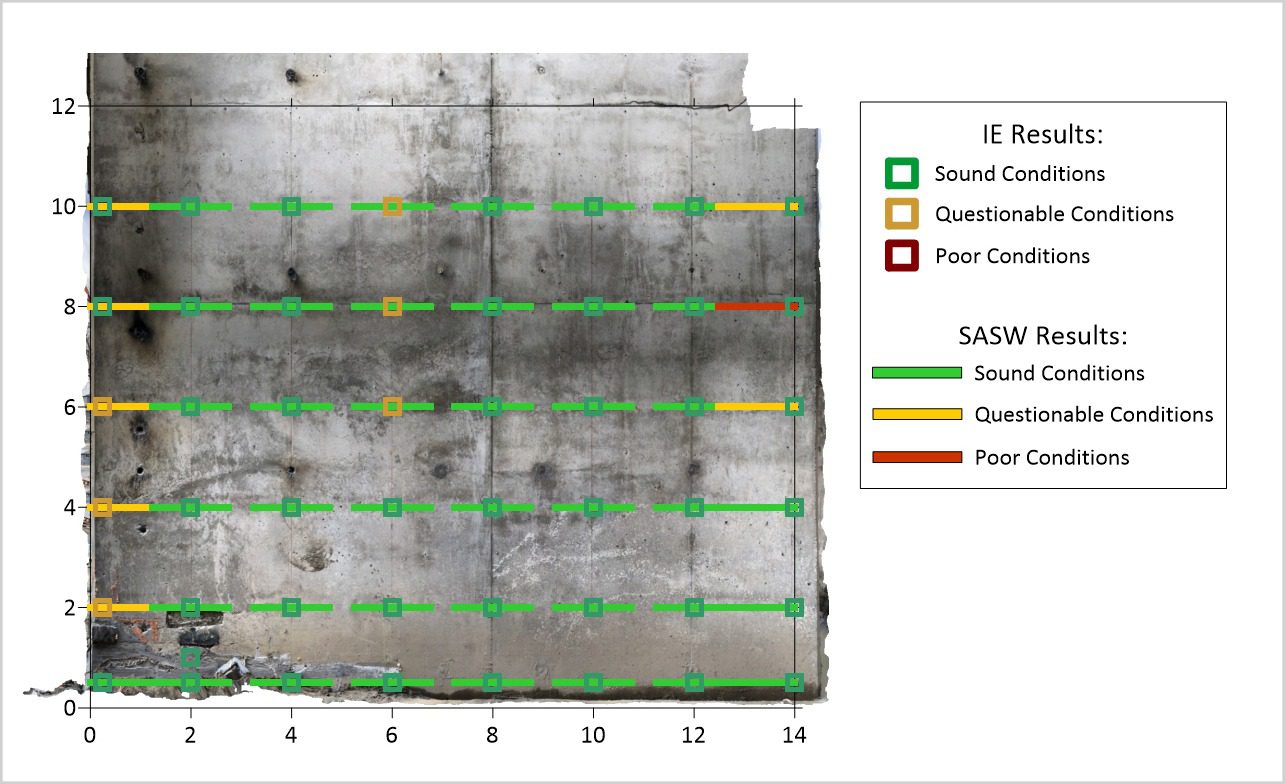

- Applicable for parallel to subparallel flaws from the surface in plate-like objects such as slabs, walls, columns, mat foundations, beams

- One-sided testing

- Flaw location and depth

- Thickness profiling without the need to drill, core or excavate

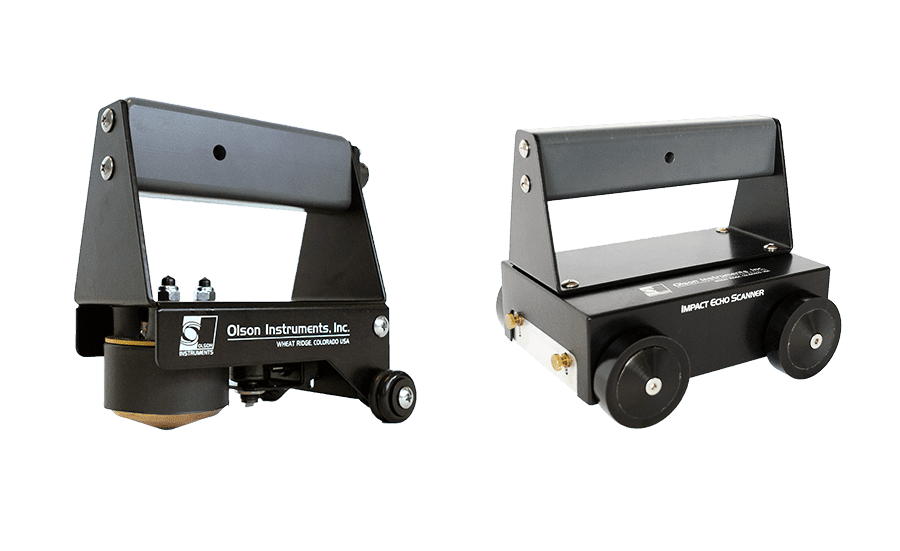

A variation of the impact echo principle is the Impact Echo Scanning (IES) method.

- Patented technology of a rolling transducer and automated impactor for near-continuous IE testing

- Fast-acquiring IE testing (1000 points/hour)

- Best for high resolution imaging of large areas for internal concrete conditions

- Example applications: slab thickness profiling and flaw detection, pavement testing, location of ungrouted sections of post-tensioning ducts

- Read a paper on the IES, as applied to PT duct void location

Applicable On:

Floors

Beams

Runways

Tunnels

Dams

Columns

Walls

Pavements

Slabs up to 24 Inches (60 Centimeters) Thick

Test For:

Thickness and Internal Cracks

Voids

Honeycomb

Delaminations

The IE & IES Test Systems

High Data Acquisition

Thousands of tests can be performed per hour when "imaging" of internal concrete conditions is required

Convenience

Only one side of the structure needs to be accessible for testing

Rapid Testing

Rapid flaw detection and thickness evaluation

Testing Specificity

The IE method provides information on the depth of a flaw or defect, in addition to mapping its lateral location and extent

Variety of Materials

This system can be used on concrete, stone, and masonry materials

Structural, Pavement, & Tunnel Methods

Foundation Depth & Integrity Methods

Geophysical Methods

Seismic

Electrical Resistivity

Electromagnetics

Ground Penetrating Radar